Ultrasonic Cleaner For PCB cleaner

- Home

- Products

- Ultrasonic Cleaner For PCB cleaner

Ultrasonic Cleaner Machine for PCB Cleaning

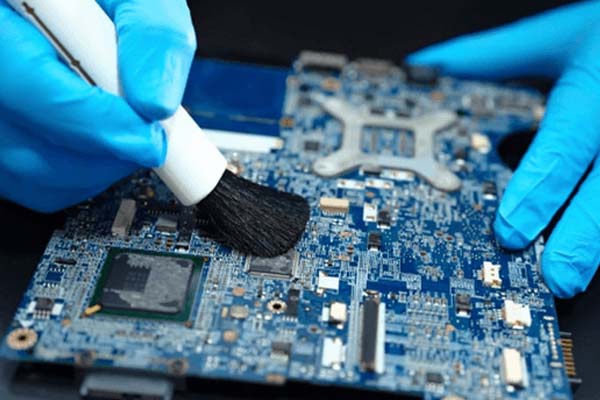

In the electronics industry, cleanliness of PCBs (Printed Circuit Boards) is critical for

performance, reliability, and product life. During manufacturing and repair, PCBs accumulate

flux residues, solder paste, dust, oils, and microscopic contaminants that can cause short

circuits, poor conductivity, and premature failures.

An Ultrasonic Cleaner Machine offers the most advanced and safe solution for deep, non-

destructive cleaning of PCBs and electronic components – ensuring consistent

performance and long-term reliability.

Where Ultrasonic Cleaner is Used for PCB Cleaning

Ultrasonic technology is widely applied in:

- Electronics manufacturing units – cleaning newly assembled PCBs before conformal coating.

- Repair and rework centers – removing flux, solder residues, and adhesives from repaired boards.

- R&D laboratories – ensuring precision cleaning for testing and prototype boards.

- Telecom, automotive, and medical electronics – for sensitive, high-performance circuit boards.

- Military & Aerospace electronics – where flawless reliability is a must.

What Happens After Ultrasonic Cleaning

Complete Removal of Contaminants

- Cleans flux residues, solder balls, dust, oils, and adhesives at micro-level.

- Penetrates under ICs, BGA packages, sockets, and fine-pitch components.

Restores PCB Performance

- Improves conductivity and prevents leakage currents.

- Enhances solderability and reliability of electronic circuits.

Prepares for Conformal Coating

- Ensures boards are completely free from impurities before protective coating.

Extends Component Life

- Prevents corrosion and overheating caused by contamination.

Why Ultrasonic Cleaning is Necessary for PCB

Miniaturization of Electronics

- Modern PCBs have micro-pitch components where manual cleaning cannot reach.

Prevents Failures

- Even microscopic residues can cause short circuits or reduced performance.

Time & Cost Saving

- Cleans multiple boards at once, faster and more consistent than manual cleaning.

Eco-Friendly

- Reduces need for strong solvents, using mild cleaning solutions instead.

Regulatory & Industry Standards

- Helps electronics manufacturers comply with IPC and ISO standards.

Why Choose Our Ultrasonic Cleaner for PCB Cleaning

- Electronics-safe ultrasonic frequency – gentle on components, powerful on contaminants.

- Temperature-controlled cleaning – safe for sensitive ICs and solder joints.

- Custom basket designs to hold delicate PCBs securely during cleaning.

- Industrial-grade stainless steel tanks with anti-static protection.

- Available in lab-scale and production-scale models.

- Proven performance – trusted by electronics manufacturers and service centers.

FAQ – Ultrasonic Cleaner for PCB Industry

Will ultrasonic cleaning damage PCBs?

- No, ultrasonic waves clean at microscopic levels without damaging tracks or solder joints.

What solution is used for PCB cleaning?

- Typically a mild water-based cleaning solution or deionized water is used for safe results.

How long does PCB cleaning take?

- Cleaning usually takes 5–10 minutes, depending on contamination level.

For efficient, safe, and professional PCB cleaning, Samarth Electronics’ Sclean

Ultrasonic Cleaners are the most reliable solution. Whether you are a PCB manufacturer,

repair center, or electronics assembler, our machines deliver precision cleaning that

boosts product quality and reliability.

Contact Samarth Electronics today and experience how Sclean Ultrasonic Cleaning

Technology can transform your PCB cleaning process!

In summary:

- Our Ultrasonic Cleaner Machine is the safest and most efficient solution for PCB cleaning – delivering deep cleaning, improved conductivity, and higher reliability for all types of electronic circuits. By using our machine, electronics companies can reduce failures, save costs, and meet international quality standards.